All MedFire Courses

Explore MedFire’s complete training catalogue — from First Aid and Fire Safety to workplace risk management. Every course is designed for clarity, compliance, and practical application, aligned with official Australian Codes of Practice.

View ResourcesFire courses

Fire Safety Advisor - Course Set

Comprehensive FSA package for assessing and advising on building fire safety systems and compliance.

View & Book

Facility Fire Safety - Course Set

Multi‑unit program covering prevention, response and small emergency confinement for facility staff.

View & Book

Fire Safety in Healthcare facilities - Course Set

Fire safety tailored for healthcare settings including response, prevention and small emergency control.

View & Book

Fire Warden, Chief Warden, Fire Extinguisher and First Attack Fire fighting training - Course Set

Packed course set for wardens and chief wardens combining evacuation leadership and firefighting skills.

View & Book

Warden and Chief Warden - Course Set

Short courses for wardens and chief wardens focused on ECO roles, communication and safety leadership.

View & Book

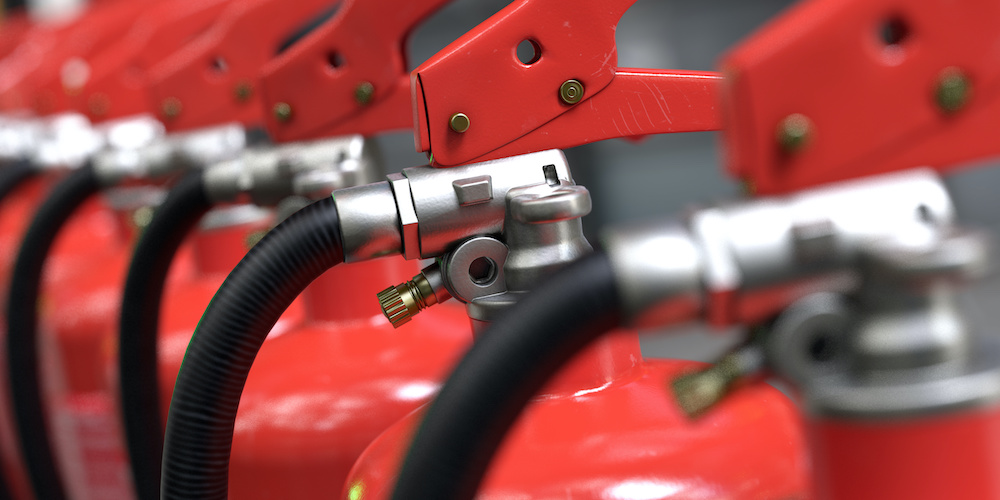

Fire Warden and Fire Extinguisher training - Course Set

Combine fire suppression with evacuation coordination — ideal for frontline responders.

View & Book

CPPFES2005 — Demonstrate first attack firefighting equipment

Practical training in selection and effective use of workplace first attack firefighting equipment.

View & Book

PUAFER001 — Identify, prevent and report potential facility emergency situations

Awareness and prevention strategies to reduce facility emergency risks and improve reporting systems.

View & Book

PUAFER002 — Ensure facility emergency prevention procedures are implemented

Systems and process implementation to support facility emergency prevention and compliance efforts.

View & Book

PUAFER003 — Manage and monitor facility emergency procedures and resources

Operational oversight of emergency equipment, drills and resource readiness for facilities.

View & Book

PUAFER004 — Respond to facility emergencies

Hands‑on response training for small emergencies and initial facility recovery actions.

View & Book

PUAFER005 — Operate as part of an emergency control organisation

ECO role training for wardens and responders working within facility emergency structures.

View & Book

PUAFER006 — Lead an emergency control organisation

Leadership and decision making for chief wardens and senior ECO personnel during incidents.

View & Book

PUAFER007 — Manage an emergency control organisation

Managerial oversight of ECO functions, communications and interagency liaison for major events.

View & Book

PUAFER008 — Confine small emergencies in a facility

Practical skills to contain small fires and limit emergency escalation in buildings.

View & Book

Fire Warden Course (Non‑accredited)

Short course covering wardens’ responsibilities, evacuation procedures and practical response steps.

View & Book

Fire Awareness — Online (non acccredited)

Short online module covering basic fire safety, prevention and workplace responsibilities.

View & Enrol

Chief Fire Warden — Online (non-accredited)

Online chief warden training focused on leadership, planning and ECO coordination (non‑accredited).

View & Enrol

Fire Warden — Online (non-accredited)

Online fire warden refresher for workplace wardens, covering evacuation and basic firefighting awareness.

View & EnrolChainsaw courses

FWPCOT2254 — Maintain chainsaws

Routine servicing, cleaning, reassembling and safe maintenance practices for workplace chainsaws.

View & Book

FWPCOT2273 — Trim and cut felled trees

Safe trimming and cutting of felled trees, recognising compression/tension and applying correct cut types.

View & Book

FWPCOT2275 — Fell trees manually (basic)

Skills for assessing and manually felling small/basic trees, plus operator maintenance and safety.

View & Book

Course Set — FWPCOT2254 - Maintain chainsaws FWPCOT2273 - Trim and cut felled trees

Combined training in chainsaw maintenance and trimming/cutting of felled trees.

View & Book

Course Set — FWPCOT2254 - Maintain chainsaws FWPCOT2273 - Trim and cut felled trees FWPCOT2275 - Fell trees manually (basic)

Maintain chainsaws, fell basic trees, and trim/cut felled trees in one comprehensive set.

View & BookCivil courses

PUAFIR207 — Operate breathing apparatus (open circuit)

Course Description

This nationally recognised unit covers the operation and maintenance of open‑circuit breathing apparatus. Participants gain the skills to safely don, operate, and maintain BA equipment in fire and industrial environments, ensuring effective use in hazardous atmospheres.

Topics Covered

- Types and components of open‑circuit breathing apparatus

- Pre‑use checks and maintenance procedures

- Donning and doffing techniques

- Operating in hazardous environments

- Emergency procedures and safety checks

- Cleaning, servicing, and storage requirements

Delivery Options

Delivered face‑to‑face with practical training in BA use. Typical duration is 1 day, including both theory and hands‑on assessment.

Entry Requirements

Participants must be physically able to wear and operate breathing apparatus. Basic English literacy and numeracy skills are required.

Assessment

Assessment includes practical demonstrations of BA operation, emergency procedures, and written knowledge checks.

Award & Certification

Statement of Attainment for PUAFIR207 — Operate breathing apparatus (open circuit).

Compliance

Delivered under the PUA Public Safety Training Package. Meets industry standards for fire and industrial safety.

Additional Information

Recommended for fire service personnel, emergency responders, and industrial workers who may be required to operate breathing apparatus in hazardous environments.

PUAFIR210 — Prevent injury

Course Description

This nationally recognised unit involves the skills and knowledge required to identify and avoid workplace hazards and risks, maintain personal safety, and report identified issues to supervisors and team members. It is designed as an introduction to safe work practices and is relevant to workplaces requiring personnel to be involved in incidents, prescribed burns, and operational aspects of emergency management.

Topics Covered

- Identifying workplace hazards and risks

- Safe manual handling techniques

- Use of personal protective equipment (PPE)

- Incident prevention strategies

- Maintaining situational awareness

- Reporting unsafe conditions

Delivery Options

Delivered face‑to‑face with practical demonstrations and group activities. Typical duration is 1 day.

Entry Requirements

Basic English literacy and numeracy skills required. Participants must be physically capable of performing safe work practices in simulated environments.

Assessment

Assessment includes practical demonstrations of safe work practices and written knowledge checks on hazard prevention.

Award & Certification

Statement of Attainment for PUAFIR210 — Prevent injury.

Compliance

Delivered under the PUA Public Safety Training Package. Meets industry standards for workplace health and safety.

Additional Information

Recommended for fire service personnel, civil construction workers, and emergency responders who require foundational injury prevention training.

Course Set — MSMPER300 Issue work permits & MSMWHS201 Conduct hazard analysis

Course Description

This nationally recognised course set combines two key safety units: issuing work permits and conducting hazard analysis. Participants learn to authorise high‑risk tasks, identify hazards, and implement controls to maintain workplace safety in civil and industrial settings.

Topics Covered

- Principles of hazard identification and risk assessment

- Conducting hazard analysis for civil and industrial tasks

- Permit‑to‑work systems and authorisation processes

- Roles and responsibilities in issuing permits

- Monitoring compliance with permit conditions

- Documentation and reporting requirements

Delivery Options

Delivered face‑to‑face with practical exercises in hazard analysis and permit issuing. Typical duration is 1–2 days depending on workplace requirements.

Entry Requirements

Basic English literacy and numeracy skills required. Participants should be employed or seeking work in industries where permit‑to‑work systems are used.

Assessment

Assessment includes practical demonstrations of hazard analysis and permit issuing, plus written knowledge checks.

Award & Certification

Statement of Attainment for MSMPER300 — Issue work permits and MSMWHS201 — Conduct hazard analysis.

Compliance

Delivered under the MSM Manufacturing Training Package. Meets industry standards for workplace health and safety and permit‑to‑work systems.

Additional Information

Recommended for supervisors, safety officers, and civil construction workers who are responsible for authorising and overseeing high‑risk tasks on site.

Course Set — MSMPER200 Work in accordance with an issued permit & RIIWHS202E Enter and work in confined spaces

Course Description

This nationally recognised course set equips participants with the skills to safely enter and work in confined spaces while complying with permit‑to‑work systems. It covers hazard identification, risk control, and safe work procedures to protect crews in high‑risk environments.

Topics Covered

- Permit‑to‑work systems and compliance requirements

- Hazard identification and risk assessment in confined spaces

- Atmospheric testing and monitoring

- Safe entry and exit procedures

- Emergency response and rescue planning

- Roles and responsibilities of permit holders and workers

Delivery Options

Delivered face‑to‑face with practical confined space entry exercises. Typical duration is 2 days, combining theory and hands‑on assessment.

Entry Requirements

Participants must be physically able to enter and work in confined spaces. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of confined space entry, permit compliance, and written knowledge checks.

Award & Certification

Statement of Attainment for MSMPER200 — Work in accordance with an issued permit and RIIWHS202E — Enter and work in confined spaces.

Compliance

Delivered under the MSM Manufacturing and RII Resources & Infrastructure Training Packages. Meets WHS requirements for confined space work and permit systems.

Additional Information

Recommended for civil construction workers, safety officers, and emergency responders who may be required to enter and work in confined spaces under permit conditions.

Course Set — MSMPER200 Work in accordance with an issued permit, MSMWHS217 Gas test atmospheres & RIIWHS202E Enter and work in confined spaces

Course Description

This nationally recognised course set combines three essential safety units: permit compliance, gas testing of atmospheres, and confined space entry. Participants gain the skills to safely authorise, monitor, and perform confined space work while ensuring atmospheric safety and compliance with permit‑to‑work systems.

Topics Covered

- Permit‑to‑work systems and compliance requirements

- Conducting hazard analysis and risk assessment

- Gas testing procedures and interpreting results

- Atmospheric monitoring equipment use and calibration

- Safe entry and exit procedures for confined spaces

- Emergency response and rescue planning

- Roles and responsibilities of permit holders and workers

Delivery Options

Delivered face‑to‑face with practical exercises in gas testing and confined space entry. Typical duration is 2–3 days depending on workplace requirements.

Entry Requirements

Participants must be physically able to enter and work in confined spaces. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of gas testing, confined space entry, and permit compliance, plus written knowledge checks.

Award & Certification

Statement of Attainment for MSMPER200 — Work in accordance with an issued permit, MSMWHS217 — Gas test atmospheres, and RIIWHS202E — Enter and work in confined spaces.

Compliance

Delivered under the MSM Manufacturing and RII Resources & Infrastructure Training Packages. Meets WHS requirements for confined space work, gas testing, and permit systems.

Additional Information

Recommended for civil construction workers, safety officers, and emergency responders who may be required to enter confined spaces, test atmospheres, and comply with permit systems.

Full Course Set — MSMPER300 Issue work permits, MSMWHS201 Conduct hazard analysis, MSMWHS216 Operate breathing apparatus, MSMWHS217 Gas test atmospheres & RIIWHS202E Enter and work in confined spaces

Course Description

This nationally recognised course set provides comprehensive training in confined space safety, breathing apparatus operation, gas testing, hazard analysis, and permit‑to‑work systems. Participants gain the skills to authorise, monitor, and perform high‑risk tasks safely in civil and industrial environments.

Topics Covered

- Permit‑to‑work systems and authorisation processes

- Conducting hazard analysis and implementing controls

- Operation and maintenance of breathing apparatus

- Gas testing procedures and interpreting atmospheric results

- Safe entry and exit procedures for confined spaces

- Emergency response and rescue planning

- Roles and responsibilities of permit issuers and workers

Delivery Options

Delivered face‑to‑face with practical exercises in confined space entry, BA operation, gas testing, and permit issuing. Typical duration is 3–4 days depending on workplace requirements.

Entry Requirements

Participants must be physically able to wear and operate breathing apparatus and enter confined spaces. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of breathing apparatus operation, gas testing, confined space entry, and permit compliance, plus written knowledge checks.

Award & Certification

Statement of Attainment for MSMPER300 — Issue work permits, MSMWHS201 — Conduct hazard analysis, MSMWHS216 — Operate breathing apparatus, MSMWHS217 — Gas test atmospheres, and RIIWHS202E — Enter and work in confined spaces.

Compliance

Delivered under the MSM Manufacturing, MSM Work Health & Safety, and RII Resources & Infrastructure Training Packages. Meets WHS requirements for confined space work, breathing apparatus, gas testing, and permit systems.

Additional Information

Recommended for supervisors, safety officers, emergency responders, and civil construction workers who require comprehensive training in confined space safety and high‑risk task authorisation.

Course Set — MSMWHS217 Gas test atmospheres & RIIWHS202E Enter and work in confined spaces

Course Description

This nationally recognised course set equips participants with the skills to safely test workplace atmospheres and enter confined spaces. It covers gas testing procedures, atmospheric monitoring, and safe confined space entry in line with WHS requirements.

Topics Covered

- Gas testing procedures and interpreting results

- Atmospheric monitoring equipment use and calibration

- Hazard identification and risk assessment

- Safe entry and exit procedures for confined spaces

- Emergency response and rescue planning

- Roles and responsibilities of workers and supervisors

Delivery Options

Delivered face‑to‑face with practical exercises in gas testing and confined space entry. Typical duration is 2 days, combining theory and hands‑on assessment.

Entry Requirements

Participants must be physically able to enter and work in confined spaces. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of gas testing, confined space entry, and written knowledge checks.

Award & Certification

Statement of Attainment for MSMWHS217 — Gas test atmospheres and RIIWHS202E — Enter and work in confined spaces.

Compliance

Delivered under the MSM Manufacturing and RII Resources & Infrastructure Training Packages. Meets WHS requirements for confined space work and atmospheric testing.

Additional Information

Recommended for civil construction workers, safety officers, and emergency responders who may be required to test atmospheres and enter confined spaces safely.

Course Set — RIIWHS202E Enter and work in confined spaces & RIIWHS204E Work safely at heights

Course Description

This nationally recognised course set combines two essential safety units: confined space entry and working safely at heights. Participants gain the skills to identify hazards, apply risk controls, and perform tasks in multi‑hazard environments while maintaining compliance with WHS requirements.

Topics Covered

- Hazard identification and risk assessment

- Safe entry and exit procedures for confined spaces

- Atmospheric testing and monitoring requirements

- Fall prevention systems and equipment

- Safe use of ladders, scaffolds, and harnesses

- Emergency response and rescue planning

- Roles and responsibilities of workers and supervisors

Delivery Options

Delivered face‑to‑face with practical exercises in confined space entry and working at heights. Typical duration is 2–3 days depending on workplace requirements.

Entry Requirements

Participants must be physically able to enter confined spaces and work at heights. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of confined space entry and working at heights, plus written knowledge checks.

Award & Certification

Statement of Attainment for RIIWHS202E — Enter and work in confined spaces and RIIWHS204E — Work safely at heights.

Compliance

Delivered under the RII Resources & Infrastructure Training Package. Meets WHS requirements for confined space work and working at heights.

Additional Information

Recommended for civil construction workers, safety officers, and emergency responders who may be required to perform tasks in confined spaces and at heights.

Course Set — MSMPER300 Issue work permits, MSMWHS201 Conduct hazard analysis & RIIWHS202E Enter and work in confined spaces

Course Description

This nationally recognised course set equips supervisors and workers with the skills to issue permits, conduct hazard analysis, and safely enter confined spaces. It provides comprehensive training in authorising high‑risk tasks, identifying hazards, and applying safe work practices in controlled environments.

Topics Covered

- Permit‑to‑work systems and authorisation processes

- Conducting hazard analysis and implementing controls

- Safe entry and exit procedures for confined spaces

- Atmospheric monitoring and compliance requirements

- Emergency response and rescue planning

- Roles and responsibilities of permit issuers and workers

Delivery Options

Delivered face‑to‑face with practical exercises in permit issuing, hazard analysis, and confined space entry. Typical duration is 2–3 days depending on workplace requirements.

Entry Requirements

Participants must be physically able to enter and work in confined spaces. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of permit issuing, hazard analysis, and confined space entry, plus written knowledge checks.

Award & Certification

Statement of Attainment for MSMPER300 — Issue work permits, MSMWHS201 — Conduct hazard analysis, and RIIWHS202E — Enter and work in confined spaces.

Compliance

Delivered under the MSM Manufacturing and RII Resources & Infrastructure Training Packages. Meets WHS requirements for confined space work, hazard analysis, and permit systems.

Additional Information

Recommended for supervisors, safety officers, and civil construction workers who are responsible for authorising and overseeing confined space tasks.

MSMPER200 — Work in accordance with an issued permit

Course Description

This nationally recognised unit provides the skills and knowledge required to work safely in accordance with an issued permit. Participants learn how to follow site controls, comply with permit conditions, and maintain safety during permitted work activities.

Topics Covered

- Understanding permit‑to‑work systems

- Roles and responsibilities of permit holders

- Site safety requirements and hazard controls

- Following permit conditions and instructions

- Communication and reporting procedures

- Emergency response requirements

Delivery Options

Delivered face‑to‑face with practical exercises in applying permit conditions. Typical duration is 1 day.

Entry Requirements

Basic English literacy and numeracy skills required. Participants must be physically capable of performing tasks in line with permit conditions.

Assessment

Assessment includes practical demonstrations of working under permit conditions and written knowledge checks.

Award & Certification

Statement of Attainment for MSMPER200 — Work in accordance with an issued permit.

Compliance

Delivered under the MSM Manufacturing Training Package. Meets WHS requirements for permit‑to‑work systems.

Additional Information

Recommended for workers in industries where permit‑to‑work systems are used, including construction, civil, and industrial sites.

MSMPER300 — Issue work permits

Course Description

This nationally recognised unit provides the skills and knowledge required to issue work permits in compliance with workplace procedures. Participants learn to assess hazards, authorise safe systems of work, and monitor compliance with permit conditions across a range of industries.

Topics Covered

- Understanding permit‑to‑work systems

- Roles and responsibilities of permit issuers

- Hazard identification and risk assessment

- Authorising and monitoring high‑risk tasks

- Documentation and record‑keeping requirements

- Emergency response and escalation procedures

Delivery Options

Delivered face‑to‑face with practical exercises in issuing and managing permits. Typical duration is 1–2 days depending on workplace requirements.

Entry Requirements

Basic English literacy and numeracy skills required. Participants should be employed or seeking work in industries where permit‑to‑work systems are used.

Assessment

Assessment includes practical demonstrations of issuing permits, hazard analysis, and written knowledge checks.

Award & Certification

Statement of Attainment for MSMPER300 — Issue work permits.

Compliance

Delivered under the MSM Manufacturing Training Package. Meets WHS requirements for permit‑to‑work systems.

Additional Information

Recommended for supervisors, safety officers, and civil construction workers who are responsible for authorising and overseeing high‑risk tasks on site.

MSMWHS201 — Conduct hazard analysis

Course Description

This nationally recognised unit provides the skills and knowledge required to conduct hazard analysis in the workplace. Participants learn structured methods for identifying hazards, assessing risks, and selecting simple control measures to reduce workplace risks before tasks are undertaken.

Topics Covered

- Principles of hazard identification

- Risk assessment processes

- Hierarchy of control measures

- Monitoring and reviewing hazard controls

- Documentation and reporting requirements

- Roles and responsibilities in hazard management

Delivery Options

Delivered face‑to‑face with practical exercises in hazard analysis. Typical duration is 1 day.

Entry Requirements

Basic English literacy and numeracy skills required. Participants must be able to engage in hazard identification and risk assessment activities.

Assessment

Assessment includes practical demonstrations of hazard analysis and written knowledge checks.

Award & Certification

Statement of Attainment for MSMWHS201 — Conduct hazard analysis.

Compliance

Delivered under the MSM Manufacturing Training Package. Meets WHS requirements for hazard identification and risk control.

Additional Information

Recommended for workers, supervisors, and safety officers who are required to identify hazards and apply risk controls in the workplace.

MSMWHS216 — Operate breathing apparatus

Course Description

This nationally recognised unit provides the skills and knowledge required to operate breathing apparatus in contaminated or oxygen‑deficient atmospheres. Participants learn how to safely don, use, and maintain breathing apparatus to protect themselves and others in hazardous environments.

Topics Covered

- Types and components of breathing apparatus

- Pre‑use checks and maintenance procedures

- Donning and doffing techniques

- Operating in hazardous or confined environments

- Emergency procedures and safety checks

- Cleaning, servicing, and storage requirements

Delivery Options

Delivered face‑to‑face with practical training in breathing apparatus use. Typical duration is 1 day, including both theory and hands‑on assessment.

Entry Requirements

Participants must be physically able to wear and operate breathing apparatus. Basic English literacy and numeracy skills are required.

Assessment

Assessment includes practical demonstrations of breathing apparatus operation, emergency procedures, and written knowledge checks.

Award & Certification

Statement of Attainment for MSMWHS216 — Operate breathing apparatus.

Compliance

Delivered under the MSM Manufacturing Training Package. Meets WHS requirements for safe operation of breathing apparatus in hazardous environments.

Additional Information

Recommended for civil construction workers, safety officers, and emergency responders who may be required to operate breathing apparatus in contaminated or oxygen‑deficient atmospheres.

MSMWHS217 — Gas test atmospheres

Course Description

This nationally recognised unit provides the skills and knowledge required to test workplace atmospheres for potentially hazardous gases. Participants learn how to safely use gas monitoring equipment, interpret results, and confirm safe entry limits before commencing work in confined or hazardous environments.

Topics Covered

- Principles of atmospheric testing

- Safe use of gas monitoring equipment

- Calibration and maintenance of gas detectors

- Interpreting gas test results

- Identifying hazardous atmospheres

- Confirming safe entry limits before work begins

- Emergency procedures for unsafe atmospheres

Delivery Options

Delivered face‑to‑face with practical exercises in gas testing and monitoring. Typical duration is 1 day.

Entry Requirements

Basic English literacy and numeracy skills required. Participants must be physically capable of performing gas testing procedures in simulated environments. PPE must be worn.

Assessment

Assessment includes practical demonstrations of gas testing procedures, equipment use, and written knowledge checks.

Award & Certification

Statement of Attainment for MSMWHS217 — Gas test atmospheres.

Compliance

Delivered under the MSM Manufacturing Training Package. Meets WHS requirements for atmospheric testing and confined space safety.

Additional Information

Recommended for civil construction workers, safety officers, and emergency responders who may be required to test and monitor workplace atmospheres before entry.

PUAFIR207 — Operate breathing apparatus (non‑fire sector)

Course Description

This nationally recognised unit covers the operation and maintenance of open‑circuit breathing apparatus, adapted for industrial, rescue, and non‑fire contexts. Participants gain the skills to safely don, operate, and maintain BA equipment in hazardous atmospheres outside traditional fire service environments.

Topics Covered

- Types and components of open‑circuit breathing apparatus

- Pre‑use checks and maintenance procedures

- Donning and doffing techniques

- Operating in industrial and rescue environments

- Emergency procedures and safety checks

- Cleaning, servicing, and storage requirements

Delivery Options

Delivered face‑to‑face with practical training in BA use. Typical duration is 1 day, including both theory and hands‑on assessment.

Entry Requirements

Participants must be physically able to wear and operate breathing apparatus. Basic English literacy and numeracy skills are required.

Assessment

Assessment includes practical demonstrations of BA operation, emergency procedures, and written knowledge checks.

Award & Certification

Statement of Attainment for PUAFIR207 — Operate breathing apparatus (non‑fire sector).

Compliance

Delivered under the PUA Public Safety Training Package. Meets industry standards for industrial and rescue safety contexts.

Additional Information

Recommended for industrial workers, rescue personnel, and emergency responders who may be required to operate breathing apparatus in hazardous non‑fire environments.

PUASAR025 — Undertake confined space rescue

Course Description

This nationally recognised unit provides the skills and knowledge required to undertake confined space rescues as part of a team. Participants learn to plan, prepare, and carry out rescues in confined spaces, applying safe work practices and emergency procedures to protect both rescuers and casualties.

Topics Covered

- Confined space hazards and risk assessment

- Rescue planning and team coordination

- Atmospheric monitoring and control measures

- Safe entry and exit procedures

- Use of rescue equipment and breathing apparatus

- Casualty retrieval techniques

- Emergency response and communication protocols

Delivery Options

Delivered face‑to‑face with practical rescue scenarios in simulated confined spaces. Typical duration is 2–3 days depending on workplace requirements.

Entry Requirements

Participants must be physically able to enter confined spaces and perform rescue tasks. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of confined space rescue, casualty retrieval, and written knowledge checks.

Award & Certification

Statement of Attainment for PUASAR025 — Undertake confined space rescue.

Compliance

Delivered under the PUA Public Safety Training Package. Meets WHS and emergency response requirements for confined space rescue operations.

Additional Information

Recommended for emergency responders, rescue teams, and safety officers who may be required to undertake confined space rescues in industrial or civil environments.

PUASAR025 — Confined Space Rescue (non‑fire sector)

Course Description

This nationally recognised unit provides the skills and knowledge required to undertake confined space rescues in industrial and non‑fire agency contexts. Participants learn to plan, prepare, and carry out rescues in confined spaces, applying safe work practices and emergency procedures tailored to non‑fire environments.

Topics Covered

- Confined space hazards and risk assessment

- Rescue planning and team coordination

- Atmospheric monitoring and control measures

- Safe entry and exit procedures

- Use of rescue equipment and breathing apparatus

- Casualty retrieval techniques

- Emergency response and communication protocols

Delivery Options

Delivered face‑to‑face with practical rescue scenarios in simulated confined spaces. Typical duration is 2–3 days depending on workplace requirements.

Entry Requirements

Participants must be physically able to enter confined spaces and perform rescue tasks. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of confined space rescue, casualty retrieval, and written knowledge checks.

Award & Certification

Statement of Attainment for PUASAR025 — Confined Space Rescue (non‑fire sector).

Compliance

Delivered under the PUA Public Safety Training Package. Meets WHS and emergency response requirements for confined space rescue operations in industrial and non‑fire agency contexts.

Additional Information

Recommended for industrial workers, rescue personnel, and non‑fire agency teams who may be required to undertake confined space rescues in hazardous environments.

RIIWHS202E — Enter and work in confined spaces

Course Description

This nationally recognised unit provides the skills and knowledge required to safely enter and work in confined spaces. Participants learn hazard identification, risk assessment, atmospheric monitoring, and emergency preparedness to ensure safe operations in confined or restricted environments.

Topics Covered

- Confined space hazards and risk assessment

- Safe entry and exit procedures

- Atmospheric testing and continuous monitoring

- Use of personal protective equipment (PPE)

- Emergency response and rescue planning

- Roles and responsibilities of workers and supervisors

Delivery Options

Delivered face‑to‑face with practical confined space entry exercises. Typical duration is 1–2 days depending on workplace requirements.

Entry Requirements

Participants must be physically able to enter and work in confined spaces. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of confined space entry, atmospheric monitoring, and written knowledge checks.

Award & Certification

Statement of Attainment for RIIWHS202E — Enter and work in confined spaces.

Compliance

Delivered under the RII Resources & Infrastructure Training Package. Meets WHS requirements for confined space work and emergency preparedness.

Additional Information

Recommended for civil construction workers, safety officers, and emergency responders who may be required to enter and work in confined spaces safely.

RIIWHS204E — Work safely at heights

Course Description

This nationally recognised unit provides the skills and knowledge required to work safely at heights. Participants learn practical fall prevention techniques, correct use of harnesses and fall‑arrest systems, and emergency procedures to ensure safety when performing tasks above ground level.

Topics Covered

- Hazard identification and risk assessment for working at heights

- Fall prevention systems and equipment

- Safe use of ladders, scaffolds, and elevated platforms

- Harness fitting, inspection, and use

- Emergency response and rescue procedures

- Roles and responsibilities of workers and supervisors

Delivery Options

Delivered face‑to‑face with practical exercises in working at heights. Typical duration is 1 day.

Entry Requirements

Participants must be physically able to perform tasks at heights. Basic English literacy and numeracy skills are required. PPE must be worn during training.

Assessment

Assessment includes practical demonstrations of working at heights, equipment use, and written knowledge checks.

Award & Certification

Statement of Attainment for RIIWHS204E — Work safely at heights.

Compliance

Delivered under the RII Resources & Infrastructure Training Package. Meets WHS requirements for working at heights and fall prevention.

Additional Information

Recommended for civil construction workers, safety officers, and emergency responders who may be required to perform tasks at heights safely.

Work Health and Safety Courses

CPCWHS1001 — Prepare to work safely in the construction industry (NSW)

Course Description

This nationally recognised unit, commonly known as the “White Card” course, provides mandatory construction induction training for workers in NSW. Participants learn how to identify hazards, use personal protective equipment (PPE), communicate effectively on site, and comply with basic construction safety requirements before commencing work.

Topics Covered

- Work health and safety (WHS) legislative requirements

- Common construction site hazards

- Risk control measures and safe work practices

- Correct use of personal protective equipment (PPE)

- Emergency response procedures

- Effective communication and reporting on site

Delivery Options

Delivered face‑to‑face in classroom settings with practical activities. Typical duration is 1 day. Successful completion is required before commencing construction work in NSW.

Entry Requirements

Participants must provide valid photo identification. Basic English literacy and numeracy skills are required. Minimum age requirements apply in accordance with NSW regulations.

Assessment

Assessment includes written knowledge checks and practical demonstrations of safe work practices and PPE use.

Award & Certification

Statement of Attainment for CPCWHS1001 — Prepare to work safely in the construction industry. Successful participants will be issued a White Card, allowing them to legally work on construction sites in NSW.

Compliance

Delivered under the CPC Construction, Plumbing and Services Training Package. Meets NSW SafeWork requirements for construction induction training.

Additional Information

Mandatory for all construction workers in NSW, including apprentices, labourers, tradespeople, and site visitors who need to access construction zones.

TLIF2010 — Apply fatigue management strategies

Course Description

This nationally recognised unit provides the skills and knowledge required to identify fatigue risks and apply practical management strategies. Participants learn how to monitor personal alertness, implement workplace controls, and reduce fatigue‑related incidents in shift work, transport, and field operations.

Topics Covered

- Understanding fatigue and its impact on safety

- Identifying signs and symptoms of fatigue

- Risk assessment and control measures

- Workplace policies and procedures for fatigue management

- Strategies for maintaining alertness during shift work

- Nutrition, hydration, and lifestyle factors

- Emergency procedures for fatigue‑related incidents

Delivery Options

Delivered face‑to‑face with practical activities and case studies. Typical duration is 1 day.

Entry Requirements

Basic English literacy and numeracy skills required. Suitable for workers in industries with shift work, transport, or extended field operations.

Assessment

Assessment includes written knowledge checks and practical demonstrations of fatigue management strategies.

Award & Certification

Statement of Attainment for TLIF2010 — Apply fatigue management strategies.

Compliance

Delivered under the TLI Transport and Logistics Training Package. Meets WHS requirements for fatigue risk management in safety‑critical industries.

Additional Information

Recommended for drivers, operators, supervisors, and field workers who need to manage fatigue risks in their daily roles.

CPCCWHS2001 — Apply WHS requirements, policies and procedures

Course Description

This nationally recognised unit provides the skills and knowledge required to apply workplace health and safety (WHS) requirements, policies, and procedures in the construction industry. Participants learn how to follow safe work practices, identify hazards, and comply with site safety protocols to reduce risks.

Topics Covered

- Understanding WHS legislative requirements

- Roles and responsibilities of workers and supervisors

- Hazard identification and risk control measures

- Safe work practices and procedures

- Emergency response and incident reporting

- Communication and consultation on WHS matters

Delivery Options

Delivered face‑to‑face with practical activities and case studies. Typical duration is 1 day.

Entry Requirements

Basic English literacy and numeracy skills required. Suitable for workers and supervisors in the construction industry who need to apply WHS procedures.

Assessment

Assessment includes written knowledge checks and practical demonstrations of applying WHS requirements and procedures.

Award & Certification

Statement of Attainment for CPCCWHS2001 — Apply WHS requirements, policies and procedures.

Compliance

Delivered under the CPC Construction, Plumbing and Services Training Package. Meets WHS requirements for construction industry safety compliance.

Additional Information

Recommended for construction workers, apprentices, and supervisors who need to demonstrate competence in applying WHS procedures on site.

Fully Accredited & Nationally Recognised First Aid courses

HLTAID009 — Provide cardiopulmonary resuscitation

HLTAID010 — Provide basic emergency life support

HLTAID011 — Provide First Aid

HLTAID012 — First Aid in an education and care setting

Non Accredited First Aid courses

Baby Talk — First aid awareness (non-accredited)

Awareness‑level first aid for parents and carers covering infant CPR and choking response.

View & Book

First Aid Training (non-accredited)

Flexible non‑accredited first aid sessions focused on workplace scenarios and refresher needs.

View & BookOnline courses

Self‑paced partner LMS and MedFire online courses you can start anytime.

Fire Awareness (non-accredited)

Introductory fire safety: recognising hazards, prevention and basic workplace response actions.

View & Enrol

Chief Fire Warden (non-accredited)

Advanced warden roles: emergency planning, coordination and leadership during evacuations.

View & Enrol

Fire Warden (non-accredited)

Responsibilities and procedures for designated fire wardens, including evacuation duties and communication.

View & Enrol

CPCCWHS2001 Apply WHS requirements, policies and procedures in the construction industry

Nationally recognised unit covering WHS policies and safe work practices for construction sites.

View & Enrol

Free 100% Online Mental Health Awareness Course for First Responders (non-accredited)

Free module supporting first responders to recognise stress, trauma responses and practical coping strategies.

View & Enrol

Concussion Management in Australian Sports (non-accredited)

Free awareness module on concussion recognition, immediate response and return-to-play considerations.

View & Enrol

Mental Health Support (non-accredited)

Practical strategies for supporting people experiencing mental health challenges in a range of settings.

View & Enrol

Driver and Road Side Safety Course (non-accredited)

Safe vehicle operation and roadside work practices, including basic traffic control and PPE guidance.

View & Enrol

First Aid Course (non-accredited)

Core first aid concepts and initial response actions for common injuries and medical emergencies.

View & Enrol

Online First Aid for Parents and Carers (non-accredited)

Child-focused first aid: choking, burns, seizures and safe response for carers and parents.

View & Enrol

Autism Spectrum Disorder (ASD) Awareness Course (non-accredited)

Learn to recognise ASD, adapt communication and provide practical support in community and workplace settings.

View & Enrol

Child at Risk Refresher (non-accredited)

Refresher on recognising and reporting child protection concerns in community and care settings.

View & Enrol

Sports Trainer Refresher Course (non-accredited)

Refresher for sports trainers covering injury management, taping basics and emergency response.

View & Enrol

Medication Administration Refresher Training (non-accredited)

Refresher on safe medication handling, administration procedures and documentation practices.

View & Enrol

Workplace Mental Health (non-accredited)

Workplace-focused mental health awareness, early intervention and supportive practices for teams.

View & EnrolCodes of Practice & Standards

All MedFire courses are aligned with official Australian standards and codes of practice. Use the links below to access the authoritative references for each training stream.

First Aid & Resuscitation

- First Aid in the Workplace – Safe Work Australia

- Australian Resuscitation Council (ARC)

- ANZCOR Guidelines – Australian & New Zealand Committee on Resuscitation

Fire & Emergency Response

- Managing Electrical Risks in the Workplace – Safe Work Australia

- Managing the Risk of Hazardous Chemicals – Safe Work Australia

- Australian Fire Engineering Guidelines – ABCB